![]()

Humidity is one of the most crucial elements in creating the perfect greenhouse microclimate because it directly impacts crop health. Greenhouse foggers (also referred to as a greenhouse fogging system, misting system or mister) ensure humidity levels remain optimal for photosynthesis—an essential part of the plant growth and development process.

Why is humidity so important to the growing process?

Plants breathe in carbon dioxide (CO2) from the atmosphere by opening their pores (stomata). When the plant’s stomata open, a chain response begins. Water is drawn up from the plant roots, moving throughout the entire plant before evaporating back into the microclimate.

This process is called plant transpiration, and it functions similarly to human perspiration. Stomata open up and allow water to escape like pores on human skin. Stomata function has a lot to do with humidity levels.

When humidity is too low, plants close their stomata, slowing the photosynthesis. Reduced CO2 levels lead to plant stress, slower growth rates and compromised yield. Under severely low humidification levels, the plant’s protective mechanisms fail to offset the stress caused by the lack of atmospheric water. Without a greenhouse fogger to induce more humidity into the microclimate, eventually, the plant will wilt and die.

Humidity control also plays a crucial part in managing vapor pressure deficit (VPD). VPD is the concept that measures the variance in pressure between the humidity inside and outside the leaf. Proper VPD management leads to thriving greenhouses and fuller yields.

How do greenhouse foggers help with humidity control?

Ideal humidification levels allow plants to open their stomata more fully, respire more CO2, maximize growth and increase yield potential. Koolfog greenhouse foggers can create consistent and ideal humidification levels for these artificial indoor microclimates.

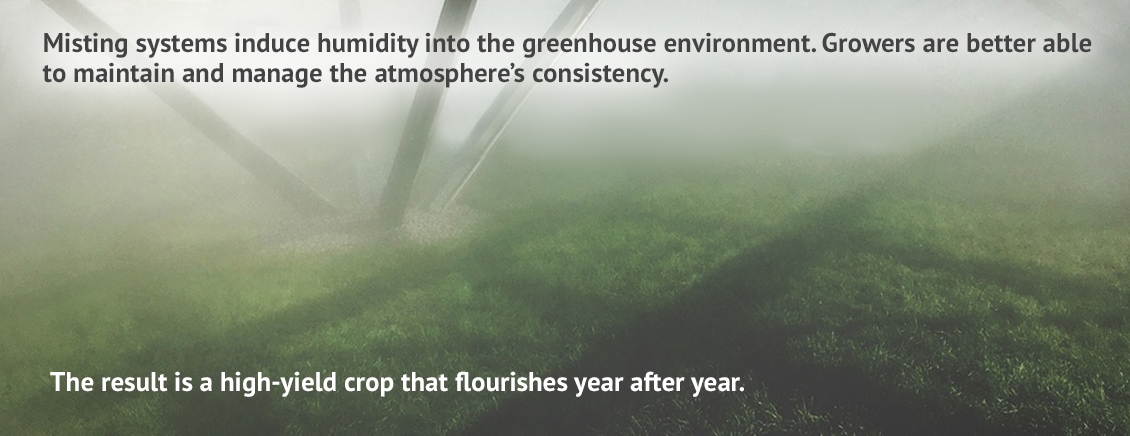

The misting systems work by inducing humidity into cultivation and growing environments, helping to maintain optimum VPD. Koolfog delivers micron-sized water droplets that, while evaporating and turning to vapor, humidify the surrounding area. These droplets evaporate before they hit the ground, which means that the crops remain dry and the relative humidity can be adjusted to a desired level.

The greenhouse foggers can be designed for screen houses, shade houses, traditional gutter-connect greenhouses and indoor operations with multiple zones. Operations have the ability to section a misting system off into multiple zones. This allows for precise humidity control throughout a facility, in different greenhouse applications and environments.

Programs that integrate with common greenhouse facility control systems allow growers to determine the best humidification levels for their particular crops. Greenhouse foggers can be used to deliver constant pressure levels, pulse output or output using variable pressures and staging, ultimately providing commercial growers with total microclimate control.

Keep in mind that a misting system’s success depends on the quality with which it was designed and manufactured. At Koolfog, each misting system is engineered to be top-quality, durable and perform at the highest standard. It starts with the materials, including 316 stainless-steel, welded fog line, multiple fog nozzle types and the highest quality components, from pump to nozzle. Growers will want to work with an expert before attempting to implement a fogger. Attempting to design a system oneself can lead to subpar results.

Any humidification solution must also be scalable to allow for changing production processes and operational growth. Ultimately, temperature and humidity control are crucial, and Koolfog humidification solutions allow for control during each day of every season.